No products

Prices are tax included

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

- Produced in Europe

- Tolerance of +/- 0.05mm

- Extra strong impact resistant

- Stable printing

- Light and durable

- Limited warping

- Notice: 1kg on the roll!

In stock online & store

VIKING FILAMENTS ABS

A strong everyday filament beyond the ordinary

Key Features:

- Limited warping

- Extra strong

- Stable print

- Lightweight and durable

- Very resistant

It is recommended to use between 90 and 110 degrees on the buildplate during printing. The nozzle temperature must be 250 degrees +/- 10 degrees.

WHY CHOOSE VIKING FILAMENTS ABS

ABS is generally an equally easy material to deal with as PLA. It is a widely used material because:

- It is robust

- Can be used for functional prints that must be particularly durable

- Very reliable material

- Great resistance

There is low humidity in the material. It can also be printed without drying it first. However, drying it will in any case lead to improved printing properties. Keep away from direct sunlight. Store dry and cool (15-25 degrees)

ABS is a robust material, but it is also known to want to warp and thus release the building board. The material should only be printed in a closed cabinet where a stable high temperature can be supported. For this, you usually have to apply glue or similar material with a slightly larger print (length / width sense), so that the highest possible bond to the building board is created. It can advantageously be an ABS juice which can be bought ready-made or made for the purpose by cutting small pieces of ABS plastic into a glass container or other container that can withstand acetone, and then fill just enough acetone in the container to have a soft mass that can be applied to the building board. You then wait for the ABS juice to dry, and can then start printing. Only apply ABS juice or glue material in the area where you want to print.

CLEAN BUILDING PLATE - ALFA & OMEGA

It is essential that the build plate is kept as clean and grease-free as possible. Many people find that their filament does not adhere well to the building board and uses glue and even hairspray.

Often, it's just a matter of cleaning your building board and keeping it clean. Start by cleaning your building board with dish soap, hot water and a scouring pad. Avoid touching the build plate while drying and reattaching the build plate to the printer. Then the building board is like new again. And after each print, wipe the building board with a cloth that has been poured a little isopropyl alcohol / isopropanol on. From time to time you can also pour a little isopropanol on the scouring pad and then scrub a little on the building board, and dry with a cloth. Then it's ready to go again!

If the above does not help, then there is a high probability that your nozzle's distance to the building board is not adjusted correctly. It may be too close or too far away. Use the paper method to roughly adjust, and then find a test pattern on e.g. thingiverse.com to print a single layer of square squares in all 4 corners and in the center. If they look the same, have a smooth surface, then the printer is adjusted correctly.

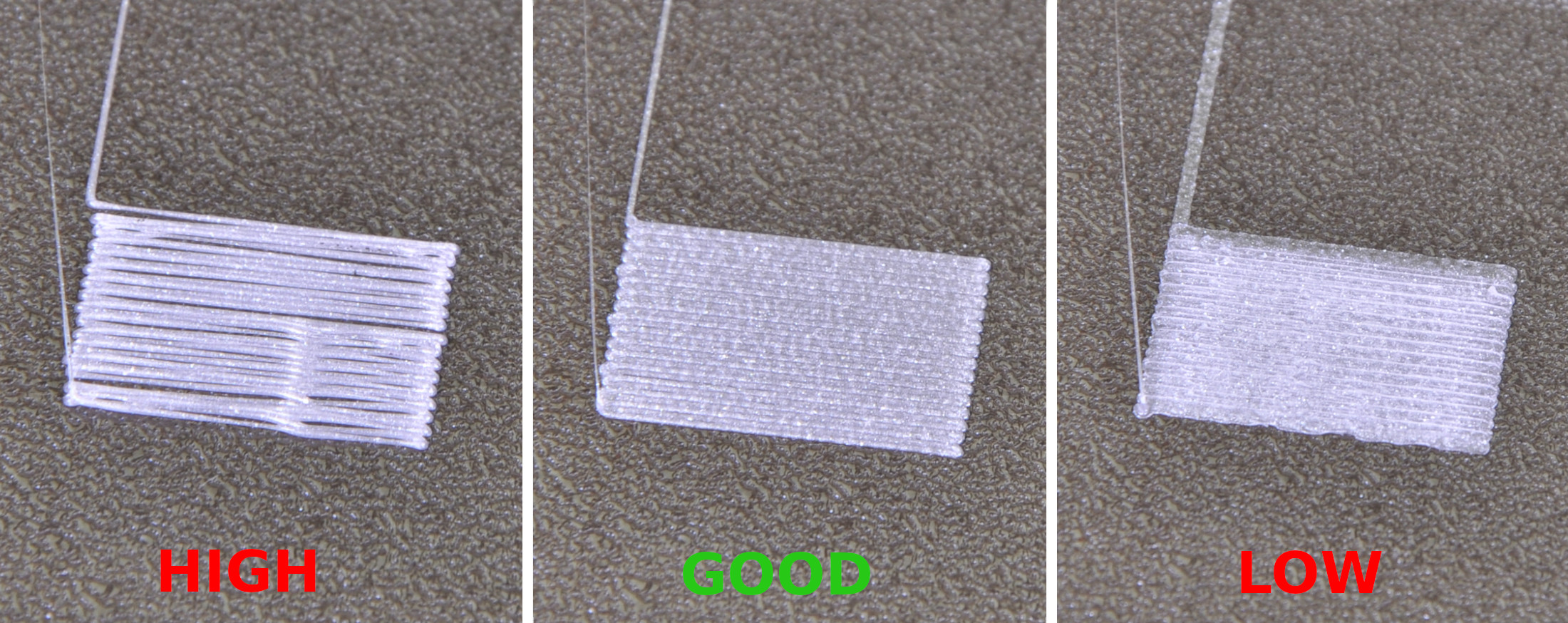

Here is the illustration of a wrong and a correct adjustment:

Source: prusaprinters.org

| Brand | Viking Filaments |

| Material | ABS |

| Diameter | 1.75mm |

| Diameter tolerance | +/- 0,05 mm |

| Color | Black |

| Weight | 1000g |

| Print temperature | 240°C - 260°C |

| Heated bed required | Yes |

| Recommended heated bed temperature | 90°C - 110°C |

| Warehouse | Store |