No products

Prices are tax included

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

3D printing slicing software controls every aspect of your 3D print.

It translates 3D models into instructions your printer understands. Better instructions mean better prints, so a simple software upgrade makes all the difference in the world.

In fact, more than 90% of experts agree that 3D printing software has the greatest impact on print quality, even more so than the 3D printer itself!

Out of stock

20450

Skriv din e-mail-adresse her, hvis du vil have besked når vi igen har denne vare på lager:

Notify me when available

Simplify3D – Easy to use slicer software for your 3D printer: Start Additive Manufacturing now

ALL-IN-ONE 3D PRINTING SOFTWARE – CAD TO G-CODE

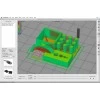

The Simplify3D software suite contains everything you need to begin making parts on your new 3D printer. Import your digital models/CAD data, select your pre-configured settings and generate your G-Code instructions in seconds. View an animated preview of your building sequence and start your 3D print knowing that you’ve optimized your model for the best possible 3D printing quality!

Note:This is a digital download. After ordering you will receive your license key by mail.

Main product features:

- Intelligent support structure

- Variable slice settings

- Vary layer height, speed, temperature

- Animated 3D print preview

- Advanced multi-part additive manufacturing

- Infill different height

- Works with most of 3D printers

UNMATCHED MANUFACTURING CAPABILITIES

Intelligent support structures

You control where breakaway support structures are placed. Use mouse clicks to add or delete supports according to your preferences. Save manufacturing time, save material, and optimize your final part with supports that break away easily and cleanly. This software is a must-have for large and complex 3D prints! Slice your CAD data into printable G-Code now.

Variable slice settings

Apply different slicing settings within the same part, such as a 40% infill base and a 15% infill top.

Select your settings

You can vary layer height, manufacturing speed, temperature, or any other setting to achieve incredible processing quality. This feature is very helpful for testing and calibration apply one setting every 10 mm and then evaluate the final part to determine your optimum 3D printing settings. This is a wonderful way to fine-tune your 3D printer capabilities.

Animated 3D print preview

Watch a fast-forward virtual animation of your 3D model being constructed. Precise views allow you to view layer-by-layer or line-by-line of your sliced CAD data. This detailed view of the building process allows you to identify improvement areas before you begin 3D printing with filament.

Advanced multi-part printing

Add 3D models as CAD data of your choice and allow the software to arrange parts to maximize your print bed capacity. You can also apply different settings for different models that are located on the same build platform. For example, if you manufacture 3 parts at once, you can choose the settings that will optimize the 3D print quality of each part. The special multi-part 3D printing mode optimizes how often the 3D printer moves between various parts to improve manufacturing quality and save

3D printing time. We simplify complex multi-part printing.

Fine outline, thick infill

Apply this setting to save time when you are using very fine

exterior layer heights. You can 3D print 3 very fine 0.1 mm outline layers while you process 1 thick 0.3 mm infill layer. It only takes one mouse click to activate this feature and it can save hours of 3D printing time yet still deliver a part with superior quality exterior detailing.

Complete control over the start point seam

This new feature that makes an enormous difference in 3D print quality by controlling the start point location for each layer. Many people refer to the residue of a start point as a zit that is left on your part. Now you can choose between 3 options that control the start point location.

- Make the start points completely random to help make a nice smooth exterior

- Optimize all start points for the fastest manufacturing speed (and typically the least oozing between layers); or

- Align all the start points to a specific location this is one of our new favorites! For example, if you were producing 4 various parts, you could choose a different start point location for each part and hide transition marks in an unused area of each part.

SEAMLESS INTEGRATION

Best of all, Simplify3D software is specifically tuned for use with your new 3D printer. It already contains all the pre-configured settings you need to start 3D printing quickly and easily. Take your manufacturing experience to the next level and get started with Simplify3D software today!

For more information visit: https://www.simplify3d.com/

Detailed software information is found at: https://www.simplify3d.com/software/

Technical Details

- The product is an electronic download that is emailed immediately following your purchase

- The software is cross platform and can be installed on Windows, Mac OS X, or Linux systems

- System Requirements: Intel Pentium 4 or higher processor, 2GB or more of RAM. Windows XP or greater, Mac OS X 10.6 or greater, Ubuntu Linux 12.10 or greater. OpenGL 2.0 capable system

- Improve 3D print quality and save time and money